Powder Coat Painting

Powder coating is a type of dry finishing process commonly used to apply a durable and protective layer of color to various metal surfaces. Here’s how it typically works:

Surface Preparation: Before the powder coating process begins, the metal surface must be thoroughly cleaned to remove any dirt, oil, rust, or other contaminants. This ensures proper adhesion of the powder coating and a smooth finish.

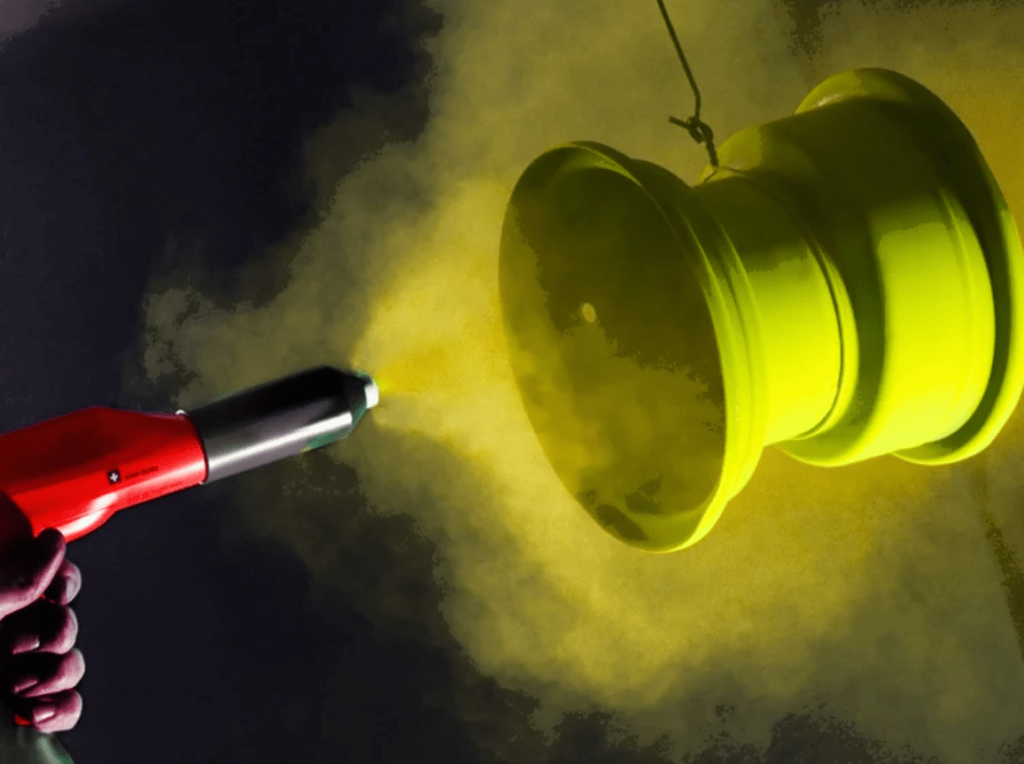

Application of Powder: The powder coating material is typically made of finely ground particles of pigment and resin. It is applied to the prepared metal surface using an electrostatic spray gun. The gun imparts a positive electric charge to the powder particles, which are then attracted to the grounded metal surface.

Curing: After the powder is applied, the metal object is moved into a curing oven. The heat in the oven causes the powder coat painting near me particles to melt and fuse, forming a solid, continuous coating. The curing process usually takes place at temperatures ranging from 300 to 450 degrees Fahrenheit (150 to 232 degrees Celsius) for about 10 to 30 minutes, depending on the specific powder coating material and thickness.

Cooling and Inspection: Once the curing process is complete, the coated metal object is allowed to cool to room temperature. It is then inspected for uniformity of coating, adhesion, and any defects that may need to be addressed.

Powder coat painting offers several advantages over traditional liquid paint finishes, including:

- Durability: Powder Paintings are highly resistant to chipping, scratching, fading, and corrosion, making them ideal for applications requiring long-lasting protection.

- Environmentally Friendly: Powder coating produces minimal volatile organic compound (VOC) emissions compared to liquid paints, making it more environmentally friendly.

- Variety of Finishes: powder coat paintings are available in a wide range of colors, textures, and finishes, including gloss, matte, metallic, and textured effects.

- Cost-Effectiveness: While the initial setup costs for powder coating equipment may be higher than for traditional painting methods, powder coating often provides cost savings in the long run due to reduced material waste, faster production speeds, and lower maintenance requirements.