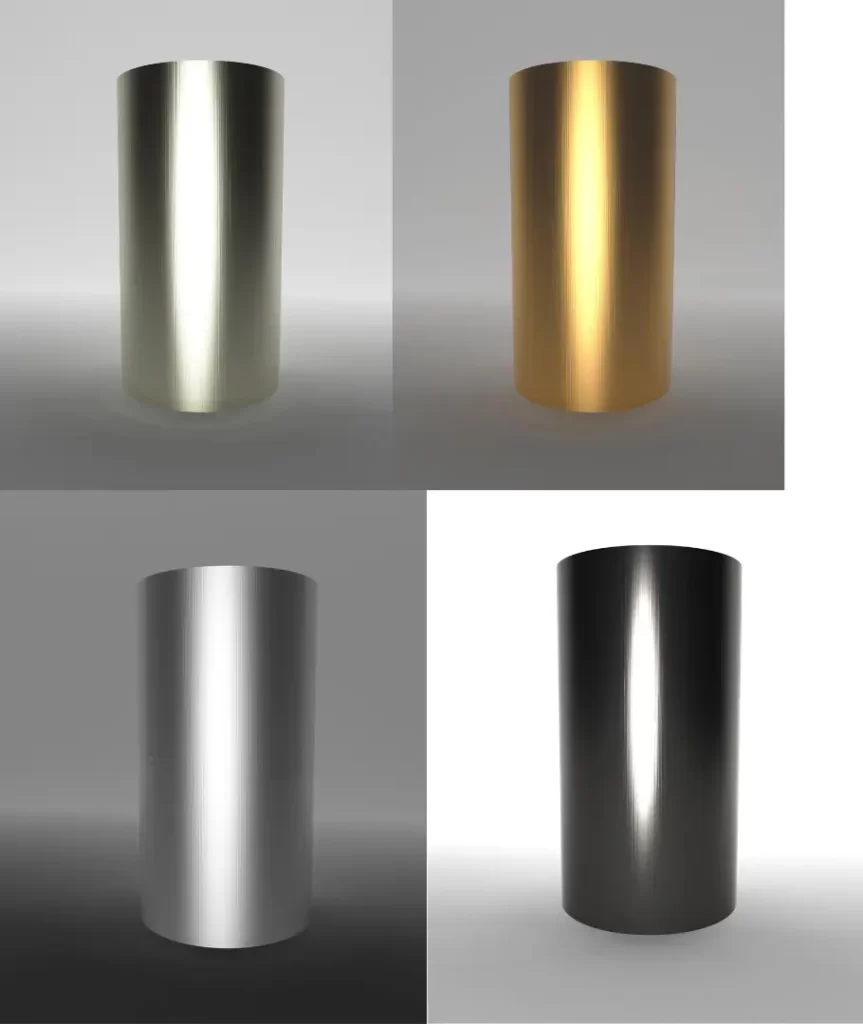

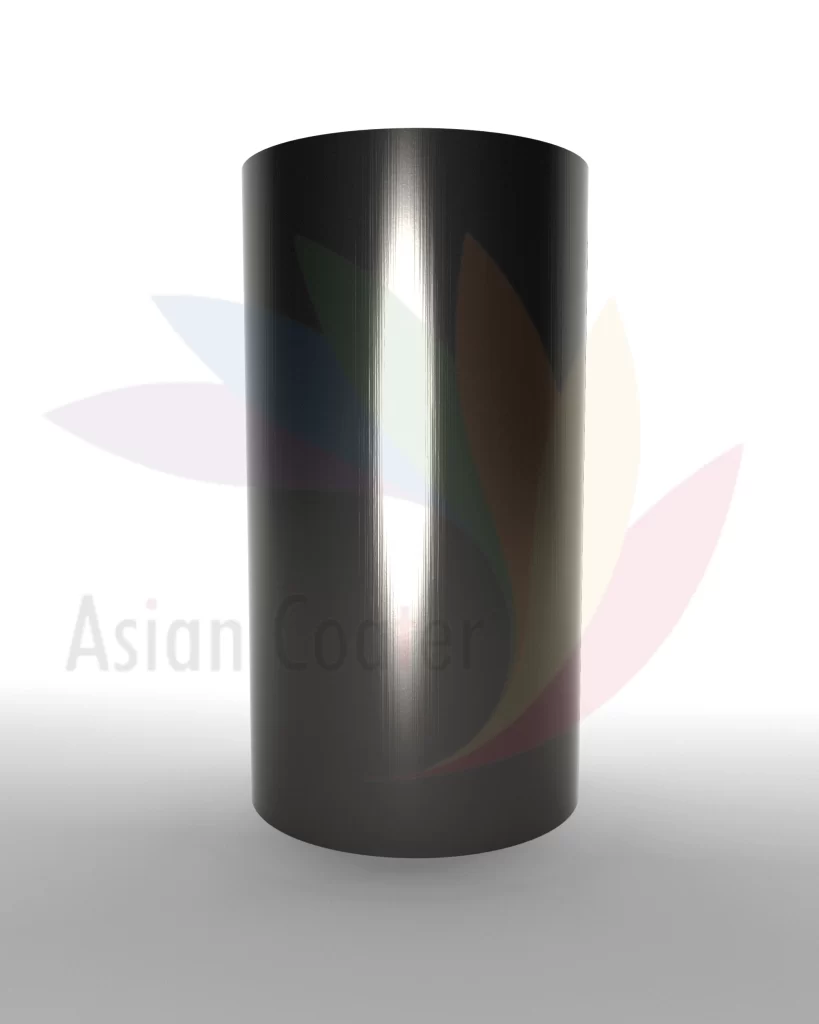

Brush Finish Anodizing

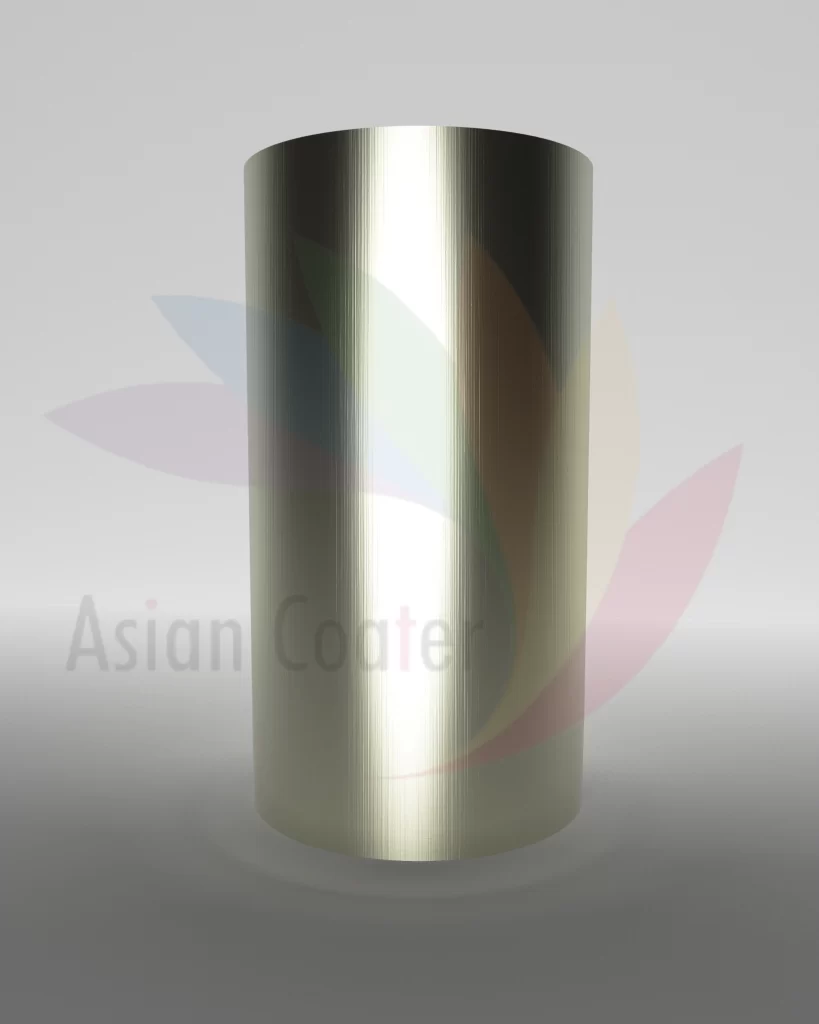

Brush finish anodizing is a specialized surface treatment process that combines the benefits of anodizing with the aesthetic appeal of a brushed metal finish. This technique involves creating a textured, brushed appearance on the surface of aluminum or other metal substrates, while also enhancing the material’s durability, corrosion resistance, and wear resistance through the anodizing process.

Brush finish anodizing offers several benefits:

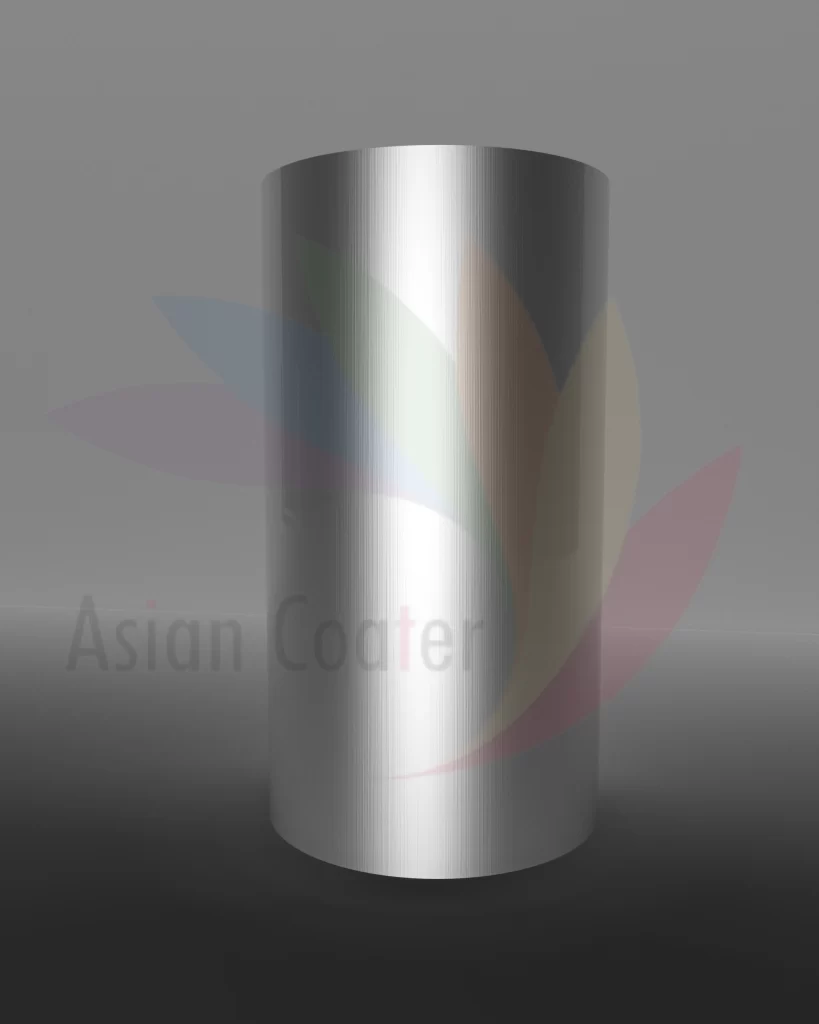

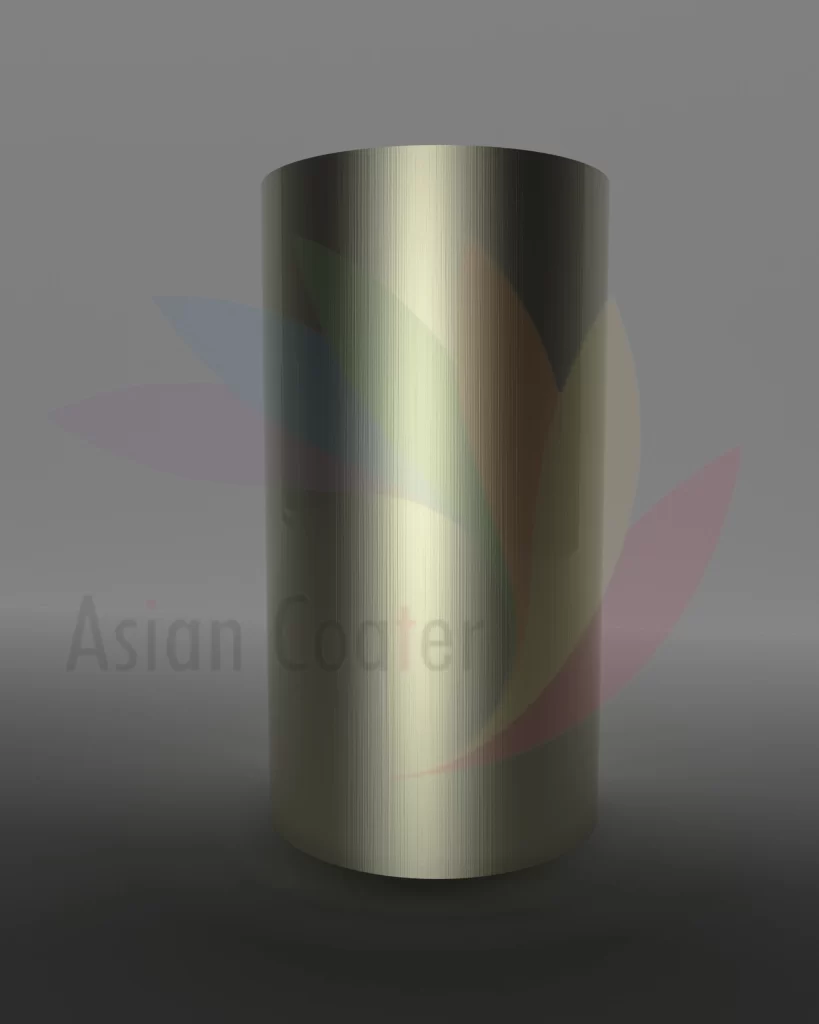

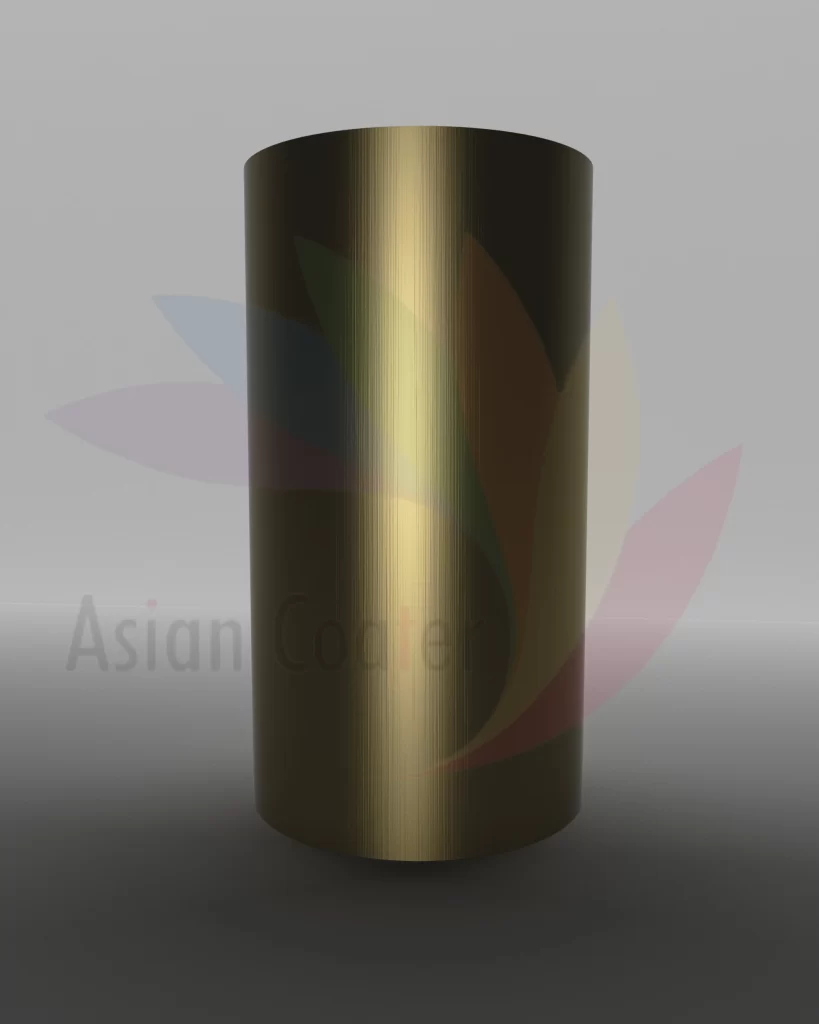

- Aesthetic Appeal: The brushed texture adds visual interest and dimension to the metal surface, giving it a modern and sophisticated appearance.

- Durability: Anodizing enhances the natural properties of the metal, making it more resistant to corrosion, abrasion, and wear.

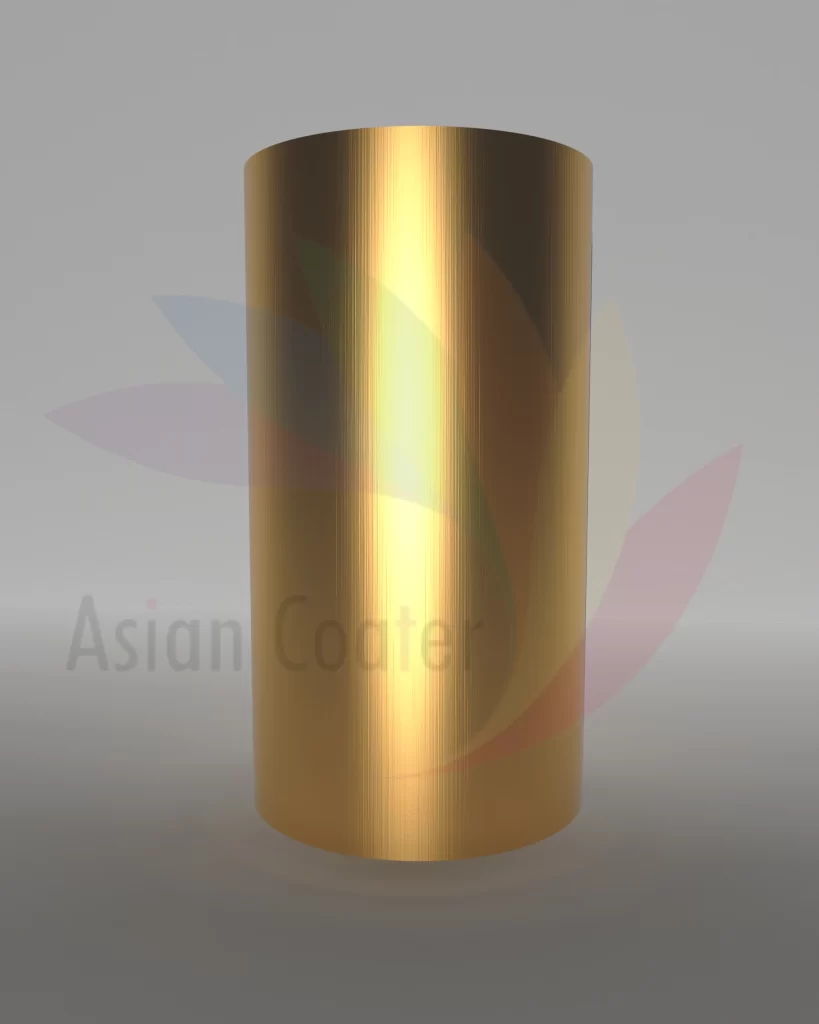

- Customization: Brush finish anodizing can be customized to achieve different brush patterns, textures, and colors, allowing for unique and personalized finishes.

- Environmental Friendliness: Anodizing is an environmentally friendly process that produces minimal waste and can be easily recycled.

Specifications : Thickness: 25 – 50 µm (.001 – .002″) thick with 1/2

Brush Finish Anodizing Service in Delhi NCR

Here’s an overview of the brush finish anodizing process:

Surface Preparation: The metal substrate is thoroughly cleaned and degreased to remove any contaminants that could affect the adhesion of the anodized finish.

Brushing: A specialized brushing technique is used to create the desired brushed texture on the surface of the metal. This can be achieved using abrasive pads, wire brushes, or other abrasive tools that create parallel lines or patterns on the surface.

Anodizing: After the brushing process is complete, the metal substrate undergoes the anodizing process. This involves immersing the substrate in an electrolyte solution and applying an electric current to stimulate the formation of an oxide layer on the surface. The anodizing process enhances the natural properties of the metal, such as its hardness, corrosion resistance, and color stability.

Dyeing (optional): In some cases, the anodized surface may be dyed to achieve a specific color or shade. This step is optional and depends on the desired aesthetic outcome.

Sealing: Once the anodizing process is complete, the substrate is sealed to lock in the anodized layer and provide additional protection against corrosion and wear. Sealing can be done using various methods, such as hot water sealing, steam sealing, or chemical sealing.

Finishing: After sealing, the substrate may undergo additional finishing processes, such as polishing or buffing, to enhance the appearance of the brushed texture and achieve the desired level of gloss or shine.

Overall, brush finish anodizing is a versatile and durable surface treatment option that combines aesthetic appeal with functional benefits, making it suitable for a wide range of applications, including architectural, automotive, and decorative applications.